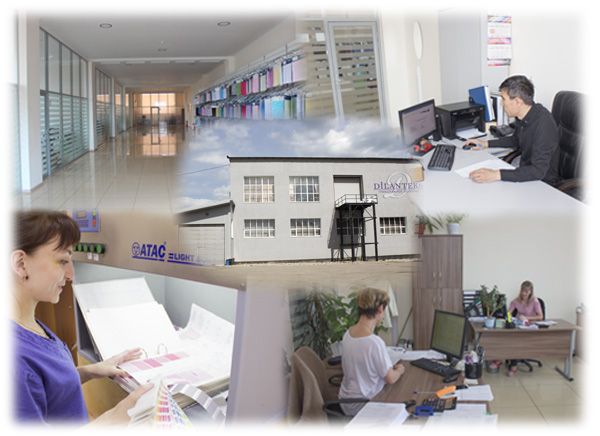

COMPANY PROFILE.

Since 2008 "Dilan-Tekstile" focuses on the policy of quality assurance, pays attention to research and development, quickly assimilates new technologies and adapts to the latest fashion trends, which allowed it to take its place among the respected and leading companies in the production of textile fabrics. For obvious reasons, you SHOULD CHOOSE THE PRODUCTS OF "DILAN-TEKSTILE", can attribute satisfaction of the demand and requirements of our dear customers who are simultaneously our business partners, also a wide range of products manufactured by our company in the Ivanovo region, where the finishing operations, works on dyeing and printing of knitted fabrics are performed in the shortest possible time work, as well as high quality of service of the friendly and professional personnel. Every step we take is aimed at unconditionally satisfying the needs of our customers, and the technical infrastructure, combined with the creative and strategic perspective, is consistent with the requirements of the information and technology era, so we can provide high-quality services, establish efficient production in Russia and thus maintain our well-deserved position in the market.

MISSION.

Carrying out systematic activities in all directions, from customer expectations to market expectations, from technological breakthroughs to innovative steps, from correct management decisions to individual success, we strive to meet all the needs of our customers and simultaneously comply with all international standards, to introduce technological innovations in product quality and to continue the successful improvement of the triangle "Producer-Customer-Manager".

QUALITY POLICY.

From the first day of its activity Dilan-Tekstile puts at the forefront the requirements and expectations of the client and to this day acts with a single goal – to best implement these requirements and expectations. Dilan-Tekstile, which is set as an example and noted by other companies, uses natural resources and company's resources most effectively, as well as takes care of the environment. Dilan-Tekstile produces high-quality products in accordance with international standards without any short-term harmful effects on the environment.

KNITING ROOM.

Total daily productivity of round-the-clock operation of 49 high-performance circular knitting machines, 2 winding machines and 6 flat knitting machines for the production of collars and cuffs is 20 tons. The yarn we take is checked in a physical laboratory, then the knitted fabric is produced in accordance with the preferences of the customers. With the help of modern circular knitting machines, a group of professional specialists produces a wide range of high-quality products based on production standards and creative imagination. In addition to the single jersey, rib knit, interlock, steel interlock, double-knit fabric, pique, terry cloth and other dyed fabric, we can produce any fabric at the request of the client.

DYE-HOUSE

Cotton and cotton blended fabrics are dyed in accordance with the highest quality standards in modern eco-friendly high-temperature dyeing machines with a capacity of 150 to 900 kg. Special dyeing machines for textile products can easily dye any kind of fabric.

FABRIC PATTERNS

Following the latest fashion trends, together with our designers we produce fabrics with numerous variants of colors and patterns and, thus, we produce for our customers a variety of uniformly dyed and printed fabric.

ROLLER PRINTING

The capacity of print-works is 7 000 kg per day. Dilan Tekstile can not only offer samples from its extensive collection, but also perform works by pre-setting the printing press according to the preferences and needs of the client

QUALITY CONTROL.

All grey fabric are subject to quality control before they go to dyeing. Each batch of products processed in the dye-house goes through an intermediate quality control after each process. All finished products are 100% inspected before shipment. We not only provide a minimum level of errors in production, but also pay great attention to the protection of the environment and human health.